In the ever-evolving field of construction, one of the most promising advancements in building reinforcement is the use of Carbon Fibre Reinforced Polymer (CFRP). Unlike traditional materials like steel and concrete, CFRP offers a unique combination of high strength, lightweight properties, and resistance to corrosion, making it an increasingly popular choice for structural reinforcement.

However, the true strength of CFRP lies not just in the carbon fibre itself, but in its integration within a plastic, or resin, matrix. This blog explores the future of building reinforcement with CFRP and highlights the critical role structural engineers play in its design and inspection.

Understanding Carbon Fibre Reinforced Polymer (CFRP)

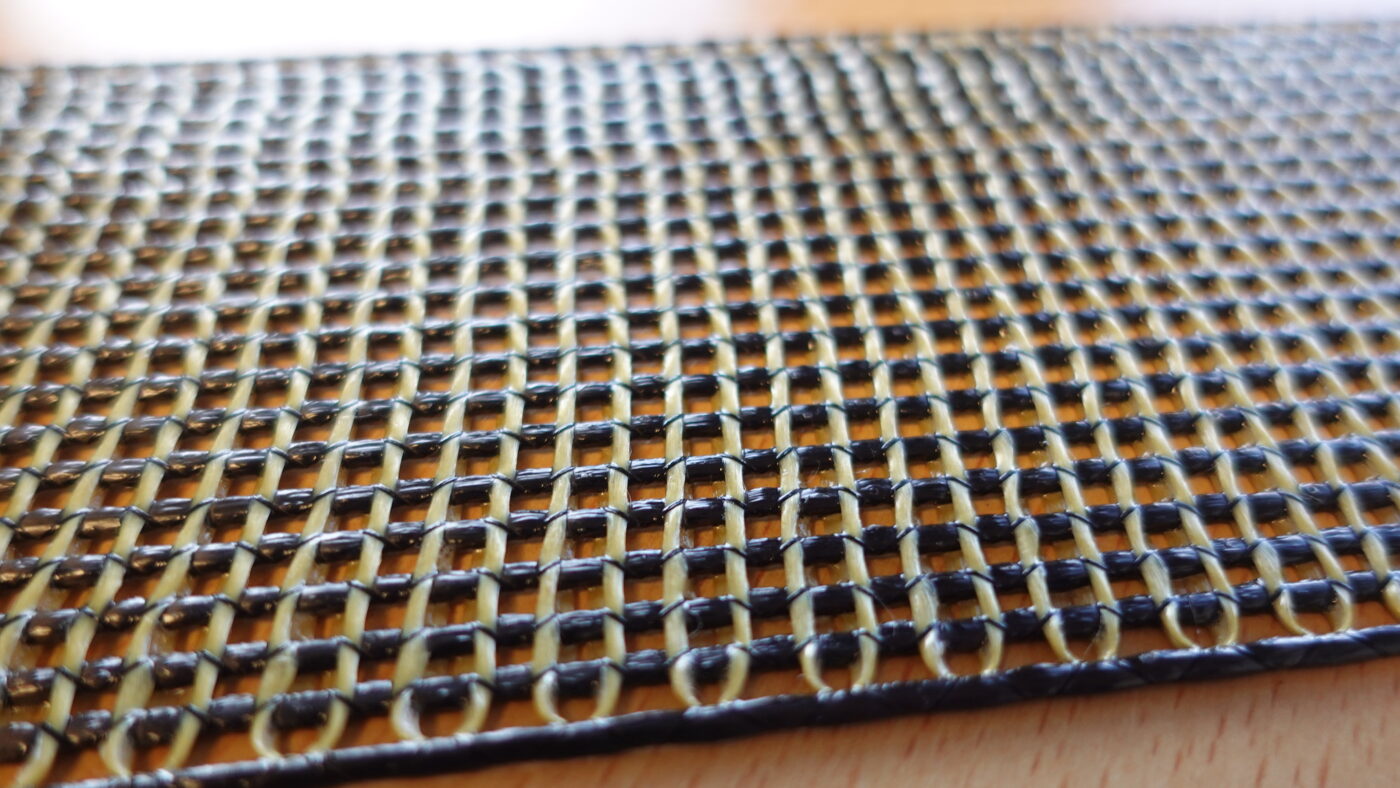

CFRP is composed of carbon fibres embedded within a resin matrix, typically an epoxy. This combination of materials results in a composite that leverages the superior tensile strength of carbon fibre along with the flexibility and durability provided by the plastic matrix. The resin binds the carbon fibres together, distributing loads more evenly across the material, which enhances its overall performance in structural applications.

This synergy between carbon fibres and the plastic matrix is what makes CFRP particularly effective in building reinforcement. The carbon fibres provide exceptional tensile strength—up to five times that of steel—while the plastic matrix contributes to the material’s resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. This makes CFRP ideal for reinforcing structures in harsh conditions, such as water and marine environments.

The Role of Structural Engineers in CFRP Application

Structural engineers are at the forefront of utilising CFRP in construction, as the material requires specialised knowledge for effective application. Engineers must carefully design CFRP reinforcement strategies that take full advantage of its properties while ensuring that the material is used where it is most needed.

One of the primary responsibilities of structural engineers is to determine the appropriate placement of CFRP within a structure. For example, CFRP can be applied to beams, columns, and slabs to enhance their load-bearing capacity without significantly increasing their weight. This is particularly beneficial in retrofitting older structures, where adding more weight could compromise the existing foundation.

In addition to design, engineers must ensure that the CFRP is properly installed. The process of embedding carbon fibres in a resin matrix requires precision, as improper application can lead to weak points in the structure. Engineers oversee the curing process of the resin to ensure that it bonds effectively with the carbon fibres and the substrate, creating a strong and durable reinforcement.

The Future of CFRP in Construction

As the construction industry continues to prioritise sustainability and efficiency, the use of CFRP is expected to grow.

The material’s lightweight nature reduces the overall load on structures, which can result in lower construction and transportation costs. Additionally, CFRP’s resistance to corrosion and environmental degradation extends the lifespan of reinforced structures, reducing the need for frequent repairs and replacements.

Ongoing advancements in CFRP technology are also making the material more accessible. Innovations in manufacturing processes are lowering production costs, which will likely lead to broader adoption across various types of construction projects. As a result, CFRP could become a standard material not just for high-profile infrastructure projects, but also for everyday buildings, including residential and commercial properties.

Conclusion

Carbon Fibre Reinforced Polymer represent a significant advancement in building reinforcement, offering a combination of strength, durability, and versatility that traditional materials cannot match. The future of construction will increasingly rely on CFRP, particularly in applications where weight, environmental resistance, and longevity are critical concerns.

Structural engineers, with their expertise in design and material science, are essential to unlocking the full potential of CFRP, ensuring that it is used effectively to create safer, stronger, and more sustainable buildings for the future.